The adult toy industry is vast, innovative, and always evolving. Behind every successful product, there's a precise manufacturing process that ensures quality, safety, and a pleasurable user experience. Whether you're considering creating your own brand or simply curious about how your favorite toys are made, understanding the manufacturing process is essential.

The adult toy manufacturing process involves design, material selection, prototyping, production, testing, and quality assurance to ensure products meet the highest standards.

In this ultimate guide, we’ll walk you through the steps behind the scenes of adult toy production, giving you an insider’s view of how these products are crafted.

Concept and Design

The manufacturing process begins with a solid concept and design. This is the most creative stage, where the product is conceptualized based on customer needs, market trends, and innovation.

Designing an adult toy requires an understanding of user preferences, functionality, and aesthetics.

Key Design Steps:

- Identifying the Purpose: Is the toy for solo play, couples, or a specific function like anal or vaginal stimulation?

- Target Audience: Who is the toy for? Are you targeting beginners, experts, or a niche market?

- Features and Functions: What will the toy do? Will it have vibrations, heat settings, or be used for penetration?

- Ergonomics: Ensuring the toy is comfortable and easy to use is crucial. The design should align with the human body, enhancing user comfort.

- Prototyping: Once the design is finalized, it’s converted into a 3D digital model for the next step in production.

The design phase is essential as it sets the foundation for the entire production process. The more thoughtful the design, the more successful the final product will be.

Material Selection

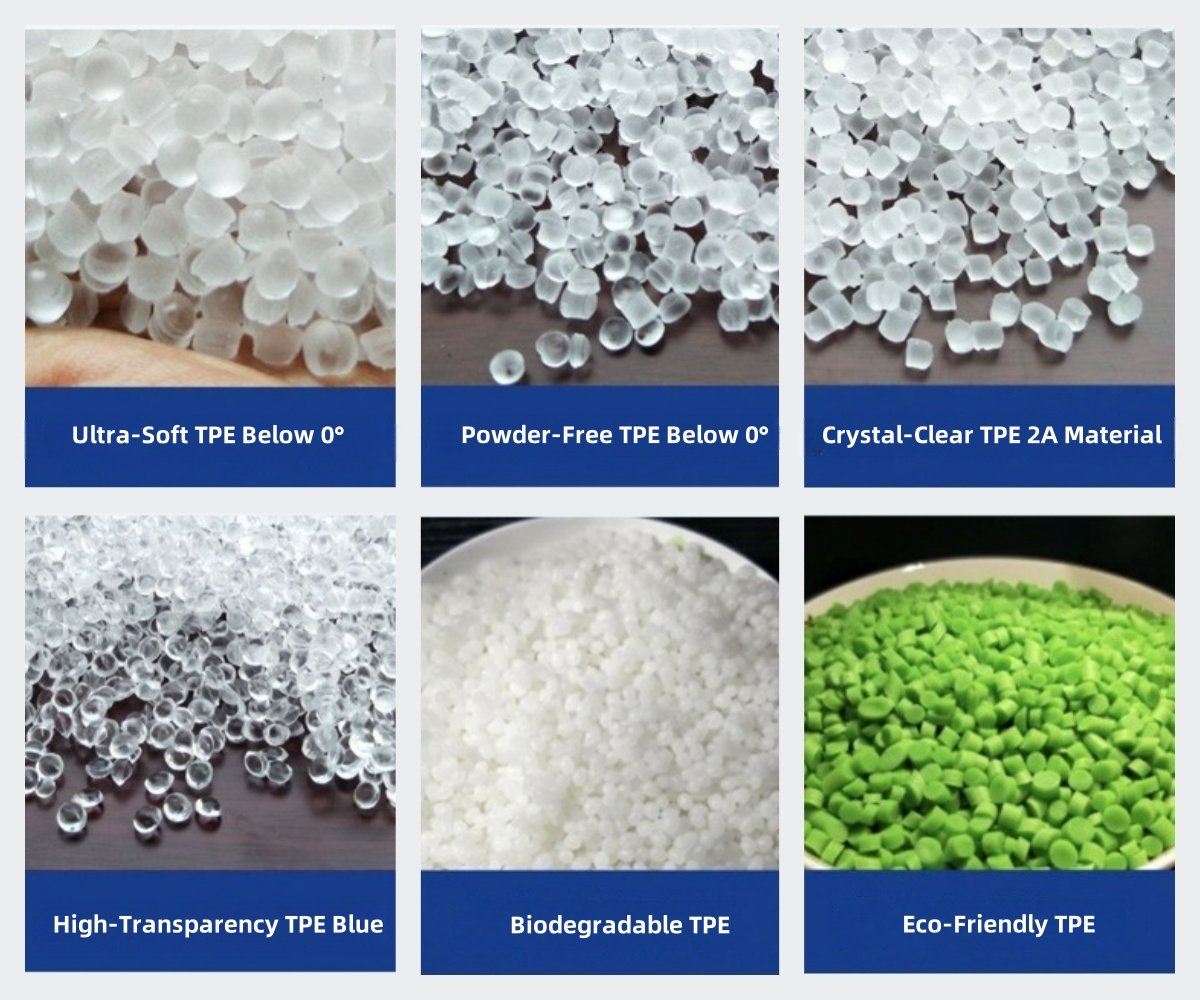

Choosing the right material is critical for the safety, durability, and comfort of the adult toy. Different materials offer different sensations, benefits, and levels of safety.

The material selection process ensures that the toy is body-safe, durable, and effective in fulfilling its purpose.

Common Materials:

- Medical-Grade Silicone: Non-porous, hypoallergenic, and durable, silicone is one of the safest materials for intimate use.

- TPE (Thermoplastic Elastomer): Soft and flexible, TPE is often used for realistic toys, offering a lifelike feel.

- ABS Plastic: Typically used for the structural parts of the toy, such as the outer casing, ABS plastic is durable and easy to clean.

- PVC: Often used for more affordable products, PVC can be made soft and flexible but requires careful attention to safety.

- Stainless Steel: For anal toys or other toys requiring a firm structure, stainless steel is a safe, durable, and easy-to-clean material.

The material chosen must meet safety standards, as well as provide the desired tactile experience. For instance, a toy designed for clitoral stimulation might require a softer material, while a vibrating dildo might need a firmer material to house internal components.

Prototyping and Testing

Once the design is in place and materials are chosen, the next step is to create a prototype. Prototyping is crucial because it turns your design into a tangible product that can be tested for functionality, comfort, and usability.

Prototyping helps identify potential flaws in design, material, or function before large-scale production begins.

Key Prototyping Steps:

- First Prototype: A sample of the toy is produced, usually by hand or with a 3D printer. This allows designers to assess the size, shape, and feel of the product.

- Functionality Testing: Testing for vibration intensity, sound level, movement, or heating mechanisms is done at this stage.

- User Feedback: Testing on a small group of users allows manufacturers to assess comfort, effectiveness, and usability.

- Refinement: Based on feedback, adjustments are made to the prototype to improve design, comfort, or functionality.

The prototyping and testing phase ensures that the final product meets the needs of the user while also adhering to safety standards. If any issues are found during testing, they are corrected before mass production begins.

Production and Manufacturing

After finalizing the prototype and design, mass production begins. Manufacturing involves creating large batches of the toy using various processes, such as molding or injection molding, depending on the materials used.

Efficient production techniques are used to ensure each toy is crafted consistently, safely, and at the highest quality.

Production Steps:

- Molding: For silicone and TPE, the material is molded into the desired shape using liquid silicone or injection molds.

- Injection Molding: ABS and other plastics are injected into molds to create the toy’s hard outer shell.

- Assembly: If the toy includes electronic components (e.g., vibration motors or heating elements), they are assembled into the toy’s internal structure.

- Curing and Finishing: Silicone toys are usually cured in an oven to harden and solidify. Afterward, the toy is finished by trimming any excess material and ensuring a smooth texture.

Production processes are carefully monitored to ensure each toy meets the required safety and quality standards. Quality assurance checks are performed throughout the production cycle to ensure uniformity.

Quality Control and Testing

Quality control is one of the most important stages in the adult toy manufacturing process. Every product must meet rigorous safety and quality standards to ensure that it is both functional and safe for use.

The final product undergoes comprehensive testing to confirm its safety, durability, and functionality before being sent to market.

Key Quality Control Steps:

- Safety Testing: Each toy is tested for potential defects, such as sharp edges or malfunctions in motors or heating systems.

- Material Testing: Tests for material quality ensure the toy is free from harmful substances like phthalates, BPA, or lead.

- Functionality Testing: The toy’s primary functions (e.g., vibrations, movement, or temperature control) are tested to ensure they work properly.

- Durability Testing: The toy is subjected to stress tests to simulate long-term use, ensuring it can withstand normal wear and tear.

- Visual Inspection: Toys are examined for defects in appearance, including surface imperfections, color inconsistencies, or any other visible flaws.

At this stage, products that pass quality control are approved for packaging and shipment, while any that fail are either reworked or discarded.

Packaging and Distribution

Once the toys pass quality assurance, they are ready for packaging. Packaging serves multiple purposes: it protects the product, attracts customers, and provides essential information about the toy.

Effective packaging plays a key role in both product protection and customer experience.

Packaging Steps:

- Protection: Packaging must protect the toy from damage during shipping and handling.

- Branding: Packaging is also an opportunity to reflect the brand’s identity, using logos, design, and colors that appeal to the target market.

- Instructions: Clear, concise instructions on use, cleaning, and maintenance are included to ensure the user has a safe experience.

- Discreet Packaging: For privacy-conscious customers, many companies use discreet or plain packaging to ensure that the product is delivered without drawing attention.

Once packaged, the toys are shipped to distributors, retailers, or directly to consumers. Distribution channels vary based on the brand’s business model, whether that’s selling through online retailers, brick-and-mortar stores, or direct-to-consumer via e-commerce.

Conclusion

The process of manufacturing adult toys is a carefully orchestrated journey, involving everything from design and material selection to quality control and distribution. By understanding the steps involved in adult toy production, consumers can better appreciate the complexity and craftsmanship that goes into creating these products.

For businesses looking to enter the adult toy industry, knowing the ins and outs of the manufacturing process is essential to ensuring the highest quality, safety, and customer satisfaction.

If you're ready to bring your own ideas to life or learn more about manufacturing adult toys, we’re here to guide you through the process — from concept to distribution.

Ken

Founder of SexLifeToday

info@sexylifetoday.com

Visit our website